Overview

The development of Radio Frequency Identification (RFID) can no longer be stopped in the field of printed circuit boards. Their reliability has long since been proven in logistics and safety technology. We specialize in designing, implementing and supporting individual RFID complete systems for printed circuit boards and assembled industry up to commissioning.

Get to know our turnkey RFID systems for the printed circuit boards and convince yourself of the many advantages that RFID technology offers you.

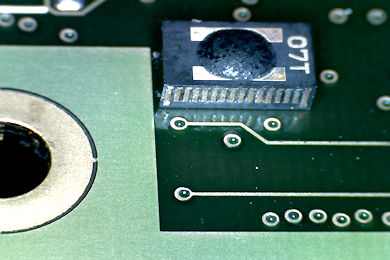

RFID SMD components, RFID printed circuit boards

RFID components SMD including the necessary antenna are our strength. Product piracy is made more difficult by RFID technology and makes it easier to trace.

RFID tags are integrated in the PCB. Traceability is guaranteed at every stage, from the electrically tested circuit board to the fully soldered, in-circuit-tested assembly.

RFID tags as adhesive labels on the printed circuit board are already state-of-the-art. Instead of barcode labels, the advantage of RFID labels is the storage of data.

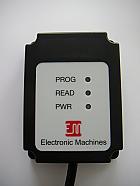

EM-RW

Stationary RFID read/write device

Frequency range 13.56 MHz

reading distance 100 mm

Scan rate reading: Vmax 6,0m/sec

Writing: dynamic

Supply voltage 10-30 V DC

RFID Software

RFID software in the electronics industry has always something to do with traceability.

In addition to the actual RFID reading software, we also offer complete traceability solutions.

RFID Solutions

An example of a complete solution is the RFID connection for SMD stencils. The robust RFID tag, which can also withstand the cleaning of the stencil, guarantees the correct stencil. Using traceability software, the correct template is reconciled with the entire line. In addition, the cleaning cycles of the stencil can be stored on the RFID tag.

Example of a solution for the service. The circuit including the circuitry is located in a housing. The RFID tag. The current software status is stored on the tag. The service staff can read the software status and the circuit number from the outside using a reader. In addition, data can be uploaded again.